|

3.6.4 Extending life

of the mountain bike

Although the Pioneer range was intended as an MTB replacement, it

was recognised that it was not a perfect substitute, its market

being somewhat different. There was therefore a need to extend the

product life of the MTB, especially for younger customers. In the

USA, interest had been growing in suspension for mountain bikes.

Alex Moulton’s dual suspension 20" wheel ATB, launched

in the USA in 1988, was probably the first fully suspended production

mountain bike. Although far from the mainstream of mountain bike

design, it stimulated interest in the subject and Rockshox telescopic

front forks reached the UK in 1990.

Adding suspension to a Raleigh MTB seemed a good way of boosting

interest and sales, hence the very successful Activator was created.

This was a budget MTB with a simple Raleigh-designed telescopic

front fork. Launched in 1992, it was advertised effectively on TV.

The following year saw the introduction of Activator II, a dual

suspension version, with a Raleigh-designed rear suspension system

somewhat reminiscent of that used on the Raleigh-manufactured Moulton

MkIII. Activator II launched at £260 (= about £315 today)

and by May 1994 could be bought at discount for £200.

Whereas the Activators were essentially budget MTBs with inexpensive

suspension designed in-house, Raleigh recognised that the other

end of the mountain bike market needing nurturing. Yvonne Rix understood

how Ford effectively used sub-brands such as Cosworth to create

interest and capture customers with aspirations higher than Dad’s

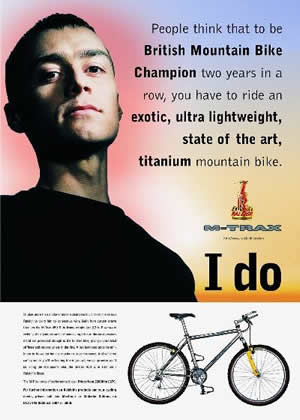

much-loved but mundane Mondeo. Hence the Raleigh sub-brand M-Trax

was developed, offering high quality MTBs. Both in marketing and

product development, M-Trax benefited from the successes of the

Raleigh Mountain Bike team, which Rix instigated in 1989.

At the MTB entry level further development was needed to sustain

interest and market share. Yvonne Rix had recognised the sales potential

of MTBs with oversize aluminium tubing, which some competitors were

introducing. However, Raleigh had no in-house aluminium frame-building

facilities and did not want to buy in frames. At the Harrogate cycle

show in 1993, Rix concluded that the appeal of oversize tubes to

younger customers was primarily visual. They liked the look but

were not particularly interested in the material used. Raleigh was

able to handle wider but thinner-walled steel tubes and hence the

Max range was born. Launched in 1995, the bikes were advertised

on TV as ‘oversized but not overweight’. The range was

hugely successful for some four years.

3.6.5

Electrically assisted bicycles

In 1998, Yvonne Rix retired as marketing director. The last innovation

she introduced was the Select electric bike, which was launched

in 1997. The Select had a proportional power control system that

automatically monitored and matched the rider’s energy input,

switching-in electric assistance only when required. It sold for

about £1,000. Rix believes firmly that electrically assisted

cycles have a big future, subject to battery improvements commensurate

with those seen in the development of mobile telephones.

Raleigh was the first major UK manufacturer to offer an electric

bike. Unfortunately, it was too early and too expensive to have

much impact on sales, and was dropped by Rix’s successor.

3.6.6

Sturmey-Archer

For a long time, Raleigh supported Sturmey-Archer by fitting an

AW 3-speed hub in the entry-level model of each range. There was,

however, an image problem with the product and a 5-speed derailleur

was a cheaper, more fashionable alternative. Moreover, Raleigh sometimes

paid more for S-A products than did competitors, which lead to internal

friction. Today S-A and Raleigh are relatively independent. There

is no special favouring by Raleigh of S-A products. A Raleigh is

as likely to have a Shimano 7-speed hub from the other side of the

world, as it is a Sturmey-Archer from the other side of the road.

Under Derby, Sturmey-Archer was able to re-engineer many of its

hubs. In most cases, this was successful, apart from the short lived

and unsatisfactory 5 StAr dual-cable 5-speed hub. A single-cable

5-speed hub, the Sprinter 5, replaced this. During the 1990s, more

than 20 years after patenting a 7-speed hub, S-A was finally allowed

to bring one to market, the Sprinter 7. Sadly, this was only after

its main rivals, Sachs (now Spectro by SRAM) and Shimano had already

introduced 7-speed hubs.

Sturmey-Archer’s main market is the Netherlands. The major

British specifiers are makers of portable cycles, such as Brompton,

and niche players such as Pashley, for their roadsters, folders

and delivery cycles, including those used by the Royal Mail.

3.6.7

1998 and after

Yvonne Rix retired in 1998. Her successor appointed a new advertising

agency and instigated a change of corporate image. Sales had been

falling at about 8% per annum for the previous two years but in

1998 they plunged 29% to 405,000, the lowest since 1970. Market

share was down from 21 to 15%, probably the lowest in a hundred

years.

At the time of writing, figures for 1999 were not available but

early indications suggested a recovery to approximately 1997 levels.

3.7

High end products: 1975-99

3.7.1 Carlton

Production of high end cycles at Nottingham ended in the late 1950s

with the Reg Harris era. Awareness of, and interest in, the demands

of the serious competitive cyclist died with it. The acquisition

in 1960 of Kevin and Gerald O’Donovan’s Carlton Cycles

generally filled this gap. However, as Carlton was for the most

part run autonomously, the association of the Raleigh brand with

performance products ceased in the UK.

The export situation was very different. Raleigh products designed

and built by Carlton were an important part of the range. They sold

well in their own right and were not used just to lend credibility

to the rest of the range.

3.7.2

Lightweights move to Nottingham

The success of Carlton was seen as diluting the Raleigh brand and

therefore the Carlton brand was killed off. Production was transferred

to a new lightweight department at Nottingham. Initially the products

were lacklustre: high specification tubing but with mass production

geometry and mid-range equipment. There was relatively little contact

with potential customers: this, coupled with Raleigh’s inherent

lack of responsiveness, led to some delay before the product met

the intended customers’ needs.

Although Raleigh had a successful racing team on the Continent,

marketing made little use of this to promote Nottingham-built bikes.

Meanwhile, serious cyclists turned their backs on the Nottingham

lightweights and beat a path to buy frame-sets from the Raleigh

team workshop, Gerald O'Donovan’s Specialist Bicycles Development

Unit at Ilkeston.

Nonetheless, the Nottingham-made product did improve and the International

Cycling Guide 1983 selected the off the peg Raleigh Team Replica

as one of its bikes of the year. Campagnolo-equipped, it sold for

£450 (= about £880 today).

3.7.3

Special Products Division

The demise of the European team in the early 1980s led to the closure

of Ilkeston but resulted in Gerald O’Donovan and Melvyn Cresswell

teaming up on product development at what became known as Special

Products Division. Shortly before this, and supported by his ‘indulgent

boss’ Yvonne Rix, Cresswell had designed and launched the Randonneur

tourer. It was based on personal experience and inspired by his

first ‘serious’ bicycle, which Gerald O’Donovan had

built for him many years previously. Although Raleigh’s most

expensive complete bicycle, it was an instant success. The Randonneur

proved that Raleigh could still sell high-end product if it was

thoughtfully designed and manufactured.

The small team gathered together at Special Products built on this

success. They produced many viable new bikes, which initially sold

in good volumes. Derby encouraged this development work and Ed Gottesman,

leader of the Derby buy-out, was particularly supportive. An avid

collector of high-end Raleighs, he was always looking to add to

his collection. Moreover, he always paid for his Special Products

bikes.

Managing director Sandy Roberts was also a keen supporter of the

unit. However, after he retired in 1990, support waned. Despite

pioneering work on thermal bonding technology (DynaTech) and frame

manufacture using titanium and metal matrix composites, the Raleigh

board was unsure how to make use of Special Products Department.

Should it be required to make a profit? Should it be a development

overhead? Was it a marketing tool and hence part of marketing costs?

Yet, even breaking even was difficult. This was the era when internal

transfer charging became fashionable in the corporate world. Despite

being autonomous, Special Products had to contribute disproportionately

to corporate IT costs, human resources department costs and even

the running of directors’ cars. Meanwhile the sales department

had little interest in Special Products and was so tied to the Raleigh

5-star dealer network that access was denied to quality independent

dealers capable of selling the product. The decline of Special Products

was therefore inevitable, although the unit still exists.

3.7.4

Special Products as niche support for volume production

The Raleigh view is that the company always has been and remains

primarily about mass-production. The brand philosophy also dictates

that Raleigh must make the best end of the bicycles sold in volume.

Therefore, if Raleigh sells mountain bikes, it must make the top

niche Raleigh MTBs. Consequently, Special Products development unit

now makes MTBs for the Raleigh team, whose mission is ‘to demonstrate

that Raleigh make the best mountain bikes in the world’. This

is not particularly profitable in its own right, but is worthwhile

because of the brand enhancement when selling ordinary bicycles.

Moreover, there is a trickle down of technological development and

refinement from the team machines to ordinary production.

The philosophy today regarding Special Products is that any niche

markets catered for must relate to the mass-produced products.

"Prices from £2000 to £270": niche products

in support of the mass market.

............................................. .............................................

|